A Distributor’s Guide to Seamless Sales and Operational Agility

Have you noticed how fast professional buyers have changed their expectations? A few years ago, a well-stocked catalog and a responsive sales rep were enough. Today, buyers arrive with the exact expectations they’ve learned from the global marketplace distributors: instant visibility into stock, transparent pricing, personalized quotes, clean product configurations, and the ability to complete complex purchases online without friction.

But here’s the real question:

How prepared are materials distributors to deliver this experience across thousands of SKUs, fluctuating surcharges, and region-specific pricing rules: all while keeping margins under control?

Many leaders tell us the same story:

Their systems work, but they don’t work together. ERP exports still drive most quoting. Pricing rules live in spreadsheets. Customer-specific terms are scattered across teams. And every time the market shifts, updating digital channels feels painfully slow.

Meanwhile, competitors who modernize their digital commerce stack are winning business simply because they make buying easier, faster, and more accurate.

That’s why this topic is so important right now.

The race is no longer about having the deepest inventory; it’s about delivering the smoothest, most innovative, and most reliable digital purchasing journey for distributors operating across multiple countries and product lines, which requires more than a webshop. It demands a unified platform where configuration, pricing, availability, and sales support all speak the same language.

We’ll explore below how materials distributors in Europe and beyond can move from fragmented legacy tools to a flexible, API-driven commerce architecture, turning operational complexity into a customer-centric competitive advantage.

Integrated Services, Configurations, and Buyer Speed

In materials distribution, the product alone is rarely “just a product.” Most orders require value-added services, cutting, bending, surface treatments, packaging sometimes in multiple combinations. For years, these configurations lived in spreadsheets, legacy CPQ systems, or slow manual quoting processes.

But today’s buyers don’t want to wait for a human-prepared quote. They expect instant clarity:

“Can this be cut the way I need? How much will it cost? And when can I get it?”

This shift has created one of the biggest competitive divides in the industry.

The Challenge: Bringing Configuration + Pricing Into One Experience

The real friction starts when configuration and pricing are split across systems.

Most distributors still struggle with:

- CPQ logic sitting outside the customer journey

- ERP rules that aren’t designed for real-time pricing

- Long refresh times for price/lead-time calculations

- Customers being redirected away from the webshop to request a custom quote

This creates a clunky experience and an immediate drop-off in conversion. One delay or one “we’ll get back to you” and the buyer is gone.

This is exactly the problem a unified commerce architecture solves.

Slize’s platform is built to unify these steps, so configuration, pricing, and delivery calculations all happen without leaving the PDP.

5 Signs You Need Unified Commerce Before ERP Migration

Enable personalized catalogs, smart logistics automation, and one unified source of truth across ERP, PIM, and CRM.

The Solution: Seamless, Real-Time Service Configuration

The most successful distributors take an API-first approach, ensuring every piece of the configuration experience stays inside the commerce flow. No detours. No waiting. No context switching.

This is where Slize naturally fits as the integration layer + pricing brain, powered by:

- Unified Commerce Orchestration: All systems (ERP, CPQ, PIM, WMS) connect via a single API layer.

- Dynamic Pricing Engine: Net prices, cutting fees, scrap logic, customer agreements, and surcharges calculated in milliseconds.

- Composable Frontend: Configuration widgets load directly on the PDP with no page reload.

Together, these components create the type of experience modern B2B buyers expect.

Custom Metal Services in Northern Europe

A major steel distributor in Northern Europe, dealing with carbon steel, stainless, and coated products needed more than simple length cutting. Their catalog included:

- Sandblasting

- Priming

- Multiple cutting combinations

- Galvanizing

- Packing and bundling options

Their challenge: provide accurate, real-time pricing and delivery for every combination of material + service, across several countries and ERP systems.

Here’s how modern distributors (and Slize clients) approach this:

Cache What Makes Sense

Caching key product attributes and service availability in the commerce layer allows instant filtering and navigation. For example:

- Which products can be cut?

- Which thicknesses allow surface treatments?

- Which mills or service centers can perform which services?

This information typically lives in the PIM, then flows into the commerce system for speed.

Real-Time Price + Lead-Time Intelligence

When a customer selects a service (e.g., sheet cut in two directions + priming), the system must instantly calculate:

- Material net price

- Scrap cost

- SKU-specific rules

- Capable-to-Promise (CTP) lead time

Dynamic Pricing Engine, which can read rules from ERP, CPQ, or internal pricing logic and calculate a final customer-specific net price in real time.

Service Flexibility Without Touching Code

Distributors shouldn’t need a developer to adjust cutting rules or update service combinations. Modern architectures handle this by:

- Managing service rules in the PIM

- Managing price logic in the pricing engine

- Keeping the commerce platform clean

New rules or treatments can be added centrally and reflected instantly on the PDP, without redeploying the webshop.

Empowering the Sales Team With Real-Time Intelligence

Digital commerce in materials distribution doesn’t replace the salesperson, it amplifies them. Even in 2025, high-value orders still involve a call, a negotiation, or a confirmation. Buyers often want reassurance:

- “Is this the right material?”

- “Can I get a better price?”

- “What’s the fastest lead time?”

Your digital platform should support two humans: the buyer navigating the webshop, and the salesperson guiding them in real time. This is where many distributors struggle: their sales teams simply don’t have the data fast enough.

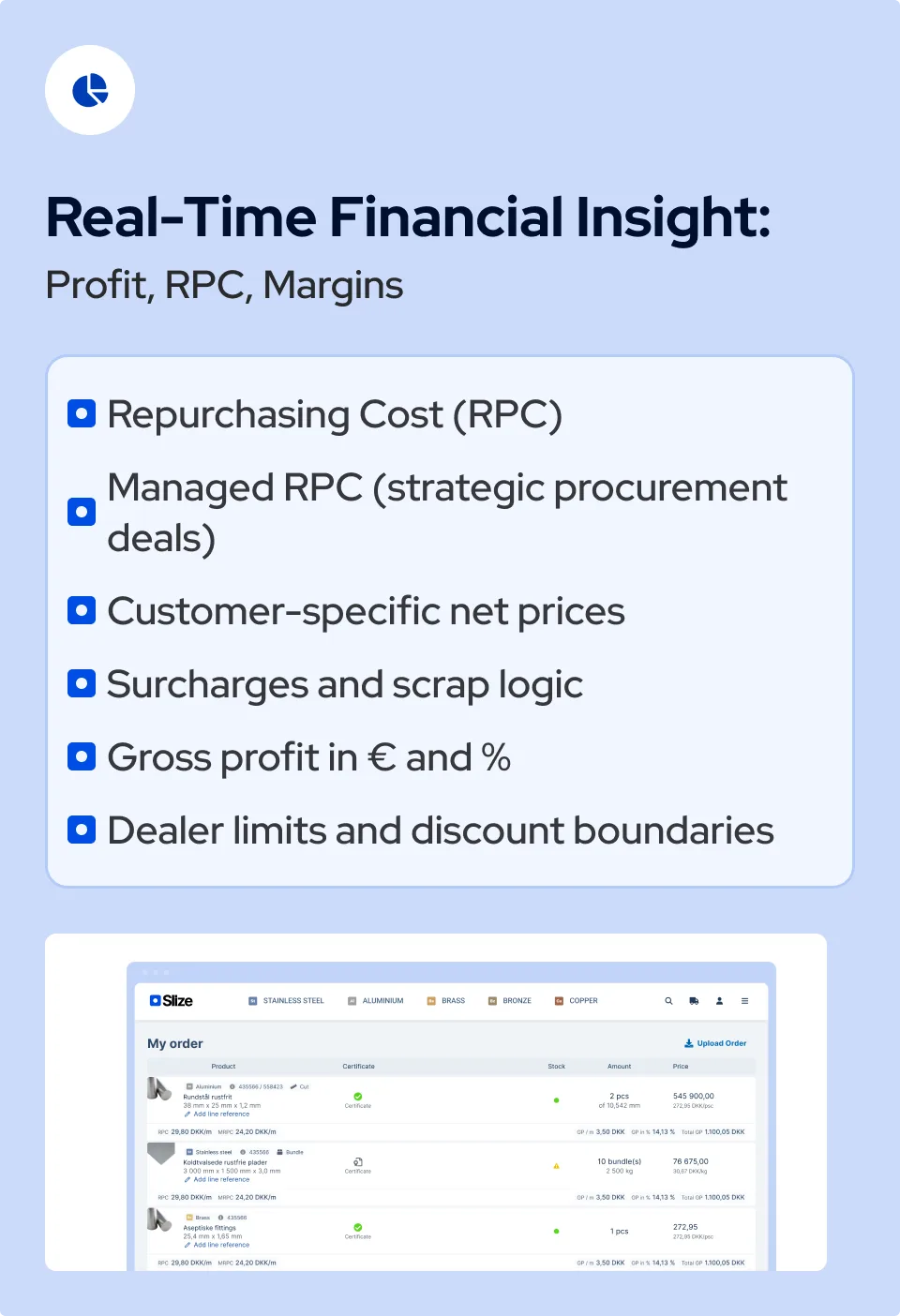

Challenge: Equipping Sales with Instant Financial Insight

Salespeople often need to access confidential financial data, negotiate discounts, or approve non-standard orders while speaking directly with the client. This requires a comprehensive, real-time view of costs, margins, and customer behavior that standard customer-facing portals do not provide.

Typical issues include:

- No unified view of customer-specific net prices

- No instant margin calculation

- Slow approval processes

- Limited insight into purchase history or price trends

- ERP data too slow or too complex for live consultation

It’s not a sales problem but a systems’ problem. And this is exactly where a platform like Slize becomes critical.

Solution: Sales-Specific Dashboards and Shadow Mode

Leading platforms offer specialized tools that allow sales representatives to operate with speed and authority:

Customer Shadowing

Sales staff can enter a “shadow mode,” logging in as the customer to immediately navigate the customer’s specific catalog, view their negotiated net prices, and place items directly into their basket. This ensures that the salesperson sees exactly what the customer sees, facilitating rapid conversational ordering.

Financial Transparency

Sales dashboards provide crucial financial context, including the naked Repurchasing Cost (RPC) the current cost to buy the material from suppliers and the Managed RPC, which might be adjusted based on strategic bulk purchases or proprietary agreements. The platform calculates the gross profit (in currency and percentage) instantly as items are added to the basket.

Historical Context and Market Trends

Sales staff have access to comprehensive purchase history, showing what other customers have bought, at what price point, and when. Furthermore, planned features include visual graphs indicating market price development over time (e.g., 12 months), enabling the sales team to interpret market shifts quickly.

Price Negotiation and Workflow Management

A distributor operating across the European steel market utilizes a streamlined quoting process. If a customer requests a price adjustment (e.g., a 10% discount) that exceeds the salesperson’s pre-approved limit (e.g., 5%), the system automatically manages the deviation:

- The sales representative proceeds with the quotation using the requested price.

- Upon submitting the quotation (the “checkout” step), an approval workflow is triggered in the backend Enterprise system (ERP).

- The quotation status remains “approval pending” until the sales manager or authorized party grants permission.

- This approach ensures the platform remains fast and user-friendly while leveraging the centralized compliance and rules engine of the backend ERP.

Personalization and Contract Management

In materials distribution, relationships are built over years, sometimes decades. Customers expect the pricing, visibility, and service levels they negotiated offline to be reflected perfectly online.

And this is where many digital platforms fall short. They can’t mirror the nuances of contract agreements, stock reservations, or specialized customer setups. As a result, buyers see the wrong prices, the wrong products, or the wrong stock levels, instantly breaking trust.

Modern B2B commerce should deliver the opposite: a digital environment that feels tailor-made for every customer.

Challenge: Managing Custom Pricing, Stock, and Contracts

Distributors need control over who sees which products and how much stock is visible, especially when dealing with volatile materials or managing specific client agreements. They should also ensure that high-volume, long-term contract items are managed accurately and priced correctly.

Every distributor knows this struggle:

- Some customers can only see certain materials

- Some should only see a portion of stock

- Some have contract pricing with fixed validity windows

- Some use their own part numbers

- Some have reserved inventory that should never appear in the general catalog

These rules often live in ERPs, email threads, spreadsheets, or someone’s memory. Digitizing them, accurately and in real time, is where the complexity begins.

Solution: Fine-Grained Customer Configuration

- Stock Visibility Control (Stock Factor): Due to fluctuations, such as in the stainless steel sector, a distributor might choose to limit exposure to specific customer segments. The platform can be configured to restrict stock visibility (e.g., showing only 40% of sheet inventory) for certain clients or segments. This control can be customized per user or customer, allowing for strategic stock allocation.

- Client Item Numbers: Distributors often work with clients who use their own internal part numbers. The digital platform allows sales teams and customers to connect client item numbers with the distributor’s catalog numbers. This two-way synchronization ensures seamless searching and ordering using the client’s preferred nomenclature.

- Contract Item Management: Customers who have dedicated agreements for reserved stock items or locked pricing must be able to view and purchase these easily. The platform identifies these items and, ideally, defaults the customer’s purchase to the contract item, ensuring the contract terms (including locked prices, where applicable) are applied automatically. Crucially, any changes or new contracts created by a salesperson that impact pricing or commitment levels would also require workflow approval to prevent system abuse.

Using configurable Stock Factors, the platform can show:

100% of stock to premium accounts

60% to standard accounts

40% or less to price-sensitive markets

Specific service centers to specific customers

Operationalizing Efficiency: Automation and Phased Rollouts

Digital transformation isn’t a “go-live moment.” It’s a long game, a continuous cycle of removing friction, upgrading processes, and introducing smarter automation where it matters most.

Distributors don’t need perfection on day one. They need practical wins today that free up time, reduce cost, and prepare them for tomorrow’s scale. And the biggest gap often appears in the most mundane place: how orders actually arrive.

The Challenge: Too Many Ordering Methods, Too Much Manual Work

Even with a fully modern web platform, customers still send orders via:

- emailed PDFs

- Excel sheets

- scanned purchase orders

- phone calls

- legacy system exports

Sales teams spend hours manually retyping order lines into ERP or commerce systems. It’s slow, repetitive, error-prone — and expensive.

The reality is that some customers will never adopt OCI or EDI integrations. But they still expect their orders to be processed quickly and accurately.

Solution: AI-Powered Order Parsing (One Push)

Forward-looking distributors are adopting AI-powered workflows that convert unstructured documents into structured digital orders, eliminating manual effort in minutes. Here’s what that looks like using a Slize-style approach:

Automated PDF Order Processing in European Distribution

A buyer emails a PDF purchase order at 7:00 AM. Before the sales team even starts their day:

- Upload or Auto-Detection: The customer or salesperson uploads the PDF — or the system reads it directly from the email inbox.

- AI Extraction: The AI identifies customer SKU numbers, product descriptions, quantities, and references. (If client-specific item numbers are mapped in the platform, they automatically convert to internal SKUs.)

- Basket Auto-Generation: A ready-to-review basket is created in the commerce platform — within seconds.

- Human Verification (One Push): The salesperson receives a notification and approves or adjusts the basket with a single click.

- ERP Sync: The order flows seamlessly into the ERP with no manual entry.

This workflow supports customers who refuse to adopt EDI but still expect lightning-fast order processing. Slize’s One-Push Order Parsing and unified catalog mapping allow this entire process to happen inside the commerce environment, reducing manual work while maintaining full auditability.

The Flexible Foundation: Preparing for Future Growth

The complexities of modern distribution demand systems that are adaptable and scalable without leading to expensive, difficult-to-maintain “tailored” solutions.

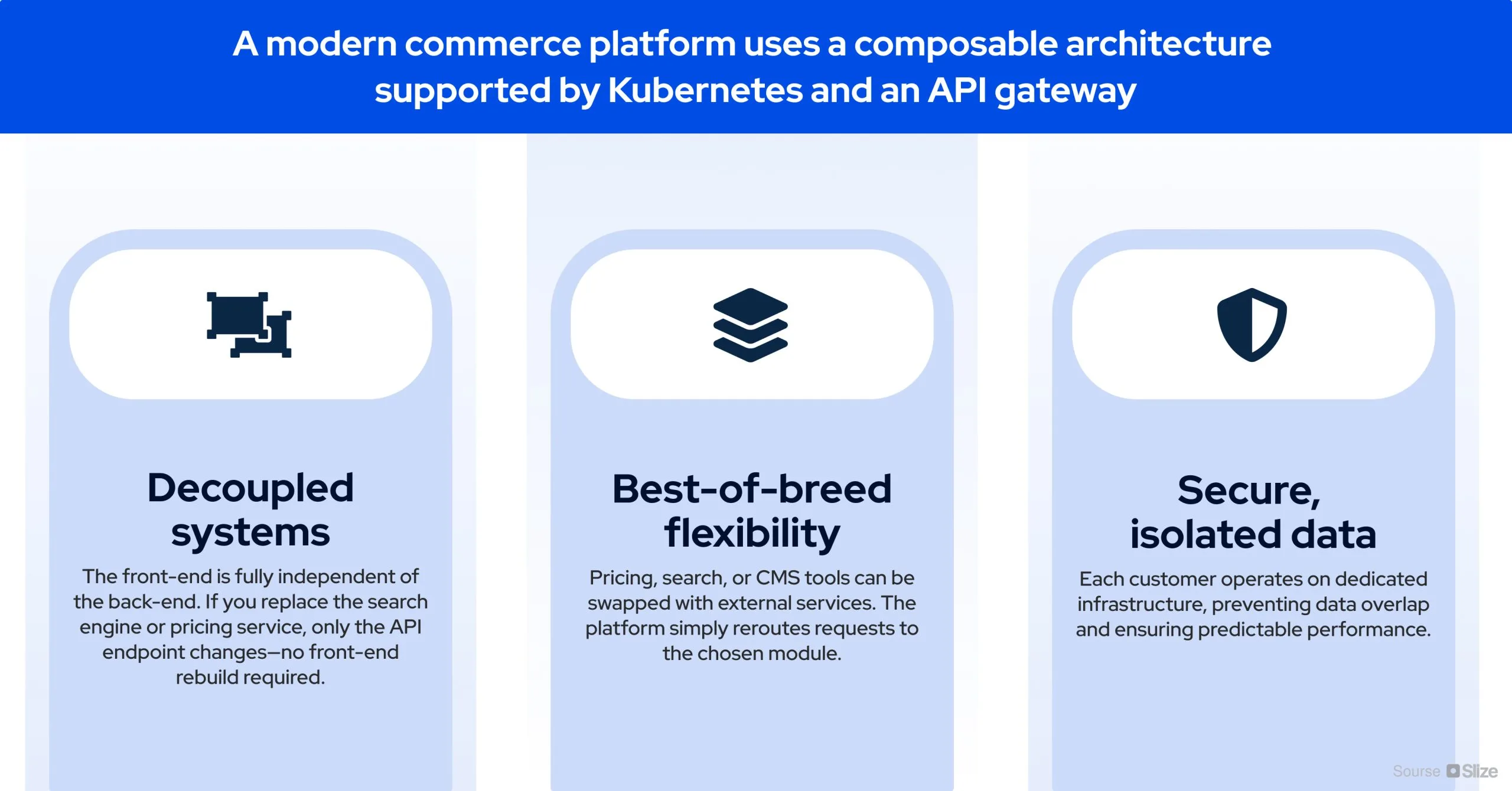

Challenge: Avoiding Vendor Lock-in and Ensuring Agility

Distributors committing to a digital platform must avoid being locked into proprietary technology, especially for fundamental services like search, pricing, and content management. Furthermore, rapid technological changes, such as new middleware choices (e.g., moving from one integration layer to another) or uncertainty regarding configuration tools, must not derail the overall project timeline.

Solution: Composable, API-First Architecture

Modern digital commerce works best when the front-end, pricing, search, and content systems are decoupled yet orchestrated through a unified API layer. This keeps the customer experience smooth while giving IT full flexibility behind the scenes.

With a composable setup:

- The front-end works independently from the back-end.

- Pricing, search, and content modules can be upgraded or replaced without touching the webshop.

- New tools or middleware can be added simply by redirecting the API gateway.

- Each client operates with isolated resources, ensuring performance and security.

The result is a digital foundation that adapts quickly to business change—without vendor lock-in, heavy customization, or long upgrades.

Future-proof your commerce architecture with modular, scalable tools for ERP, pricing, and service orchestration.