How to manage stock availability in a volatile market

Wholesale B2B distributors — especially those handling industry components, raw materials, or commodities — operate in constant volatility. From shifting tariffs (e.g., recent measures on Indian steel exports) to supply-chain shocks, accurate availability and stable pricing aren’t ‘nice to have’ — they’re the competitive edge.

Outdated legacy systems, slow ERPs, and disconnected e-commerce front-ends fail to meet these demands. They create data silos, leading to frustrated customers, delayed orders, and significant margin erosion. The solution lies in adopting a unified digital commerce platform built specifically to handle commercial complexity and deliver real-time data synchronization across all operations.

Below, we’ll share how wholesale distribution companies — regardless of whether they sell steel, electrical components, CNC tooling, or general industrial parts — can manage a composable digital backbone to master stock availability and profitability in a volatile market.

Establishing a Digital Backbone: Real-Time Data and Unified Systems

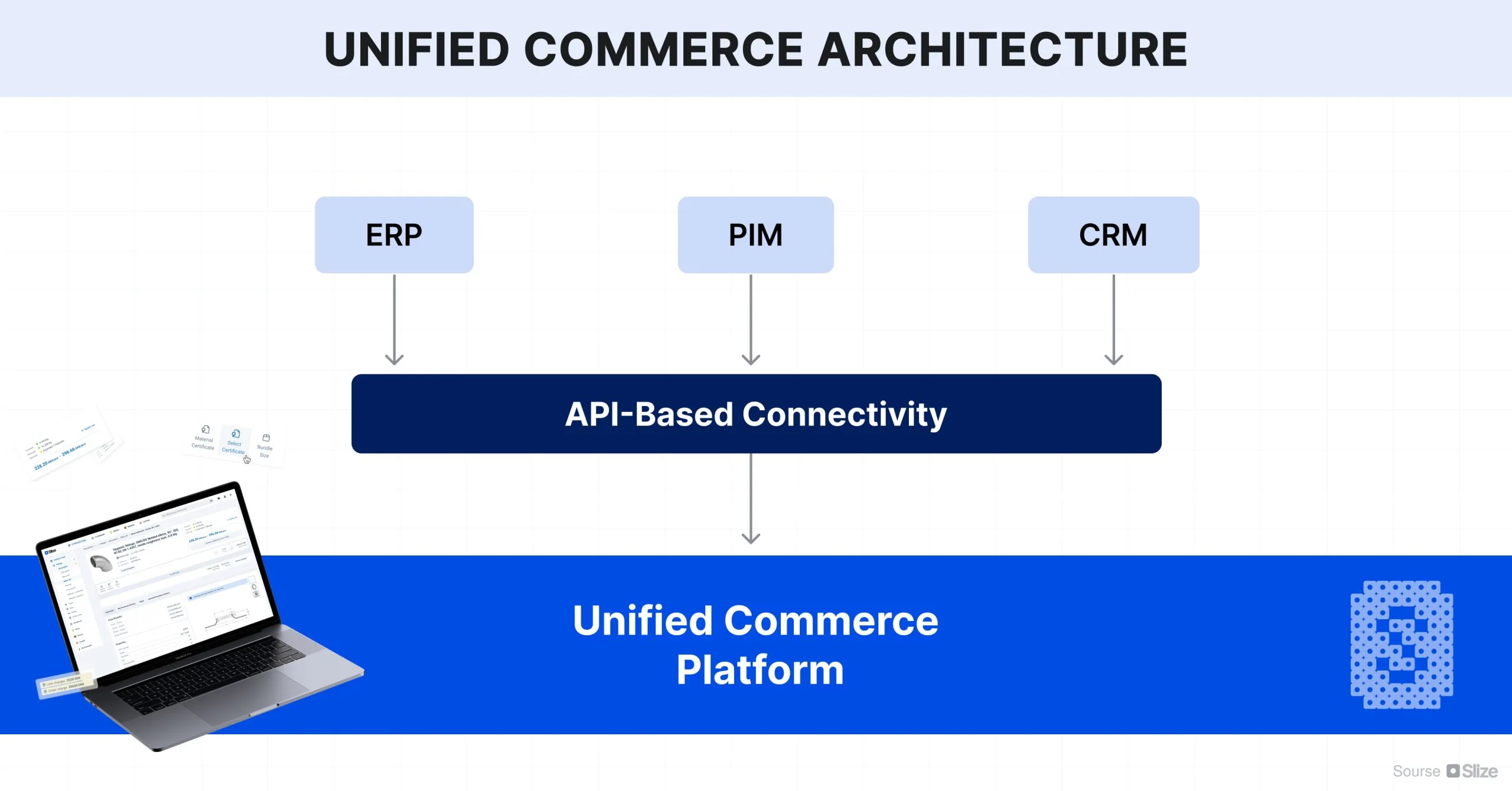

The foundation for managing stock availability efficiently is real-time visibility. In wholesale B2B, systems like the Enterprise Resource Planning (ERP), Product Information Management (PIM), and Customer Relationship Management (CRM) are often fragmented, creating data silos that impede speed and accuracy.

A unified commerce platform addresses this by acting as an operational backbone, deeply integrating with existing enterprise systems via modern API-driven architectures.

Bridging Fragmented Systems and Multi-ERP Complexity

Many large industrial enterprises operate with multiple ERP systems across different countries or subsidiaries. This fragmentation makes consolidated inventory reporting nearly impossible with traditional solutions.

A composable B2B platform must be designed for this multi-ERP reality. For example, the platform is proven to unify data from five different ERP systems across various countries for a global manufacturer like Vargus. This capability is critical during phased ERP migration or upgrades (e.g., transitioning from SAP to Infor), ensuring that stock, pricing, and order status updates are fetched directly and accurately from all active backend systems, guaranteeing business continuity.

Furthermore, modern platforms utilize API-based connectivity to link these systems and eliminate manual data entry, ensuring real-time data synchronization across the entire ecosystem. This architecture not only eliminates data silos but also provides unmatched flexibility and prevents vendor lock-in.

Built for Industry Scale and Speed

Speed and reliability are non-negotiable, especially when dealing with high order volumes and complex catalogs. The platform must be built to scale, handling vast amounts of data without compromising performance.

For instance, the platform is built to scale, managing millions of product requests daily. Damstahl, a large European steel distributor, handles 11 million requests per day with unmatched speed. This high-performance capacity ensures that customers can quickly navigate product catalogs and check stock availability, a key competitive advantage emphasized by company leaders.

Managing Volatility through Dynamic Pricing and Inventory Control

Market volatility, often characterized by sudden price shifts driven by geopolitical events or tariffs, directly threatens margins and stock planning. For industries dealing with raw materials like steel, where tariffs on Indian exports can lead to potential annual losses of up to US$2 billion and a domestic price drop of US$34.50, precise, real-time pricing and stock control are essential for survival.

Real-Time Pricing Engine for Margin Protection

Traditional ERP systems often struggle to keep pace with dynamic market cost fluctuations. An advanced pricing engine is necessary to automate adjustments and protect profitability.

Key features enabling this control include:

Repurchasing Cost (RPC) and Management RPC (MRPC): The system uses RPC to reflect real-time pricing based on current material costs (today’s supplier price).

Granular Rule-Based Pricing: This level of detail allows for highly differentiated pricing and helps manage billions of possible price combinations for clients with tens of thousands of SKUs.

Volume-Based Price Brackets: The platform supports setting up quantity discounts, rewarding bulk buyers while maintaining profitability.

This dynamic control has tangible results: Damstahl achieved 24% higher gross profit margins on digital orders compared to phone orders, translating to an estimated €6-8 million increase in profit annually for a company with a €300–400M turnover.

Stock Factor Control to Prevent Panic Buying

In volatile or shortage-driven markets, a critical challenge is managing customer expectations and preventing inventory depletion due to “panic buying”. The Stock Factor feature allows distributors to customize inventory visibility based on specific criteria.

This strategic inventory control can:

- Prioritize Loyal Customers: Grant your most loyal and valuable customers full stock access while strategically limiting the visible inventory for other segments.

- Handle Multi-Location Logistics: The system can move complex multi-location inventory logic online. This includes configurable fulfillment rules, such as depleting stock from specific regional warehouses in a predetermined order (e.g., Norway first, then Denmark, and only up to 50% from Germany, as implemented by Damstahl). The system ensures that orders are fully qualified for the ERP, eliminating the need for human verification and speeding up processing times.

Empowering Customers with Robust Self-Service

Modern B2B buyers expect the same speed, transparency, and ease of use found in retail commerce. They demand the ability to browse products, check real-time inventory, and place orders online without relying on sales representatives, which is a key solution to poor customer self-service.

A comprehensive client self-service portal, as part of a unified commerce platform, streamlines operations and improves the purchasing journey.

Seamless Ordering and Information Access

The optimized B2B webshop must provide real-time stock visibility and multi-warehouse availability directly on product list pages.

Key self-service features include:

Simplified Ordering: Features like Quick Order, the ability to save Favorite Items and multi-item number support (Customer Item Numbers, Supplier Item Numbers) streamline repeat purchases and ensure accuracy.

Contract Items and Price Stability: To secure stock for long-term partners, the platform supports Contract Items, guaranteeing availability and price stability through long-term agreements accessible only to contracted buyers.

Instant Document Retrieval: In regulated industries (like steel or manufacturing), customers need instant access to critical documents. The portal provides immediate access to saved orders, invoices, packing slips, and Certificates detailing chemical and mechanical properties.

Handling Industrial Complexity in the Cart

Unlike generic platforms, a solution built for industrial B2B must natively handle complexity. This includes supporting complex units (kilos, meters, bundles), providing visibility into leftover materials, and facilitating cutting and bundling services. Customers must be able to configure customized product packages online, reducing manual intervention and potential errors.

Optimizing Sales Team Workflows for Speed

When stock availability is complex and prices are volatile, the sales team becomes a crucial buffer. However, many B2B sales teams are burdened by manual processes, order approvals, and working within slow ERP systems, leading to delays and errors. This inefficiency represents a significant cost: sales teams can save up to 60% of their time by moving processes online compared to slower legacy systems.

A unified commerce platform provides dedicated tools to empower sales teams, allowing them to focus on growth rather than administrative work.

See how unified commerce platforms reduce manual work by 80%.

The Shadow Mode and Accelerated Order Entry

The Shadow a User feature is a cornerstone of efficient sales support. It allows sales representatives to log in as their assigned customers to:

- Provide Real-Time Assistance: Sales reps gain full visibility into the customer’s specific pricing, customized stock visibility, orders, and certificates.

- Eliminate Purchasing Barriers: The rep can place orders or troubleshoot issues instantly on the customer’s behalf.

This functionality drastically reduces reliance on the core ERP for daily operations. Damstahl, for example, reduced order entry time by 80% using the platform’s features, resulting in the savings equivalent of 48 full-time roles annually through automation of over 80,000 manual order lines.

Data-Driven Insights and Automation

Sales teams must be equipped with data to make smarter pricing and availability decisions.

- Customer Insights Dashboard: This tool provides real-time visibility into customer behavior, tracking which products customers are browsing versus purchasing. This comparison helps identify hidden sales opportunities, allowing sales reps to engage in proactive, data-driven conversations.

- Smarter Pricing Decisions: Sales reps can leverage historic price data and real-time market insights to quickly adjust prices within the system, optimizing negotiations and maintaining competitiveness.

- AI Order Automation (Upcoming): The platform is developing future AI-driven tools that will extract and match order data from customer PDFs and emails, automating basket creation and further reducing manual effort and errors.

Driving Measurable Results

In a competitive and volatile wholesale market, managing stock availability and pricing volatility is a high-stakes operational challenge. Relying on fragmented systems and manual processes inevitably leads to lost sales and margin erosion.

By adopting a composable, unified commerce platform, B2B wholesale distributors can establish the digital backbone necessary to thrive:

Accelerated Digital Growth: Clients like Damstahl scaled their digital orders 10x, from 98M to 956M DKK (approx. €12M to €128M) in just 18 months.

Operational Efficiency: Automation saved the equivalent of 48 full-time roles annually and reduced order entry time by 80%.

Increased Profitability: Digital orders yielded 24% higher gross profit margins compared to traditional phone orders.

This strategic investment ensures that industrial B2B companies can ensure business continuity, maintain real-time accuracy in stock and pricing, and emerge stronger in volatile market conditions.

Continue exploring: How unified commerce reshapes industrial B2B distribution.